Geometric Dimensioning and Tolerancing (GD&T) is a system used in design and manufacturing that defines the allowed variants in kind, orientation, and location of functions on a part. It serves as an universal language for makers and designers, assisting to interact the style intent plainly and successfully. GD&T integrates a set of symbols that represent various sorts of geometric control, which are essential for ensuring component performance and manufacturability. Comprehending GD&T symbols and guidelines can significantly boost the top quality of engineering illustrations and add to smoother production procedures.

To start with, GD&T symbols are standard and defined in the ASME Y14.5 requirement, which implies they have global approval in design self-controls. Each icon shares specific details concerning the resistance applied to an attribute. Symbols for flatness, straightness, cylindricality, and circularity show the allowed discrepancy from the optimal geometric form. Monotony, represented by a two-dimensional symbol, makes certain that a surface area is consistently flat within defined restrictions, which is important for surface areas that require to mate or secure. Comprehending and applying these symbols precisely can help protect against inequalities and assembly concerns, enhancing product integrity.

Discover GD&T symbols and guidelines the significance of Geometric Dimensioning and Tolerancing (GD&T) in engineering and manufacturing, as it enhances communication, precision, and cost-efficiency while minimizing errors via standard symbols and guidelines.

In enhancement to develop controls, GD&T also consists of orientation controls, such as parallelism, perpendicularity, and angularity. Understanding exactly how to define and interpret these alignment symbols is pivotal for specific manufacturing and top quality engineering.

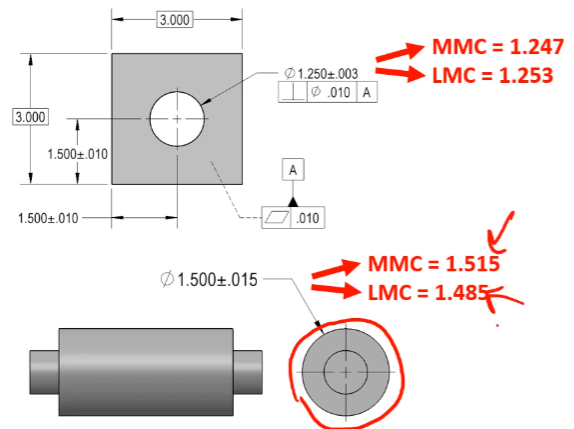

Area manages such as placement, concentricity, and balance are also necessary elements of GD&T. Positioning an attribute accurately is vital in guaranteeing that components can be put together without trouble. The position sign, as an example, makes sure that ports or holes lie at specified collaborates within a specified tolerance area. Concentricity is used to make sure that cylindrical functions are lined up along an usual axis, which is particularly important in applications needing rotational proportion. Learning to apply these place symbols properly will aid engineers in accomplishing useful components that meet style requirements while also simplifying the manufacturing procedures entailed.

An additional critical element of GD&T is the idea of information, which are referral points or surfaces that act as a basis for measurement. The efficient use information is basic in ensuring consistent production high quality. Each information is designated a letter classification, and it supports the component to sector criteria, making certain that dimensions are dependable and repeatable. Properly defined datums allow engineers to control variations much more successfully, lowering the opportunity of mistakes in production. These referrals aid in developing a durable coordinate system that all resistances can relate back to, making it important for any type of style engineer to have a solid understanding of exactly how to build and use information referrals.

When a developer specifies resistances utilizing GD&T symbols, it lowers the uncertainty frequently associated with standard dimensioning methods. In sectors where precision and top quality are vital, such as aerospace or medical tool manufacturing, the duty of GD&T in improving interaction can not be overstated.

Furthermore, the application of GD&T is valuable for expense effectiveness in production. Engineers that master GD&T can considerably affect the cost-effectiveness of their designs without compromising high quality or efficiency.

Many educational resources, workshops, and training courses are currently readily available to aid designers and engineers discover the subtleties of GD&T. Practical applications of GD&T in instance studies can offer insight into exactly how appropriately applied symbols lead to boosted top quality and lowered scrap rates in manufacturing.

When editing or translating engineering drawings that use GD&T, interest to information is extremely important. Designers have to ensure that they understand the implications of each symbol and that the drawing accurately communicates the designer's intent. Keeping a regular strategy to GD&T symbols within a company is critical. Having a standard collection of guidelines for just how GD&T is made use of in layout records can prevent misunderstandings and blunders throughout divisions. Standardization advertises a society of top quality and uniformity, enhancing the relevance of GD&T concepts in day-to-day design technique.

Discover mmb vs mmc the relevance of Geometric Dimensioning and Tolerancing (GD&T) in design and production, as it improves communication, precision, and cost-efficiency while minimizing mistakes via standard symbols and guidelines.

In final thought, mastering GD&T symbols and guidelines is an essential ability for contemporary engineers, specifically those included in design and production. By spending in proper training and exercising the efficient application of GD&T principles, designers can take advantage of this powerful device to drive advancement and excellence in their layouts, eventually leading to a more affordable and successful product growth lifecycle.

Comments on “Addressing the Challenges of GD&T Implementation for Engineers”